13 Modern Prefab Cabins Available to Order

Introduction and Outline

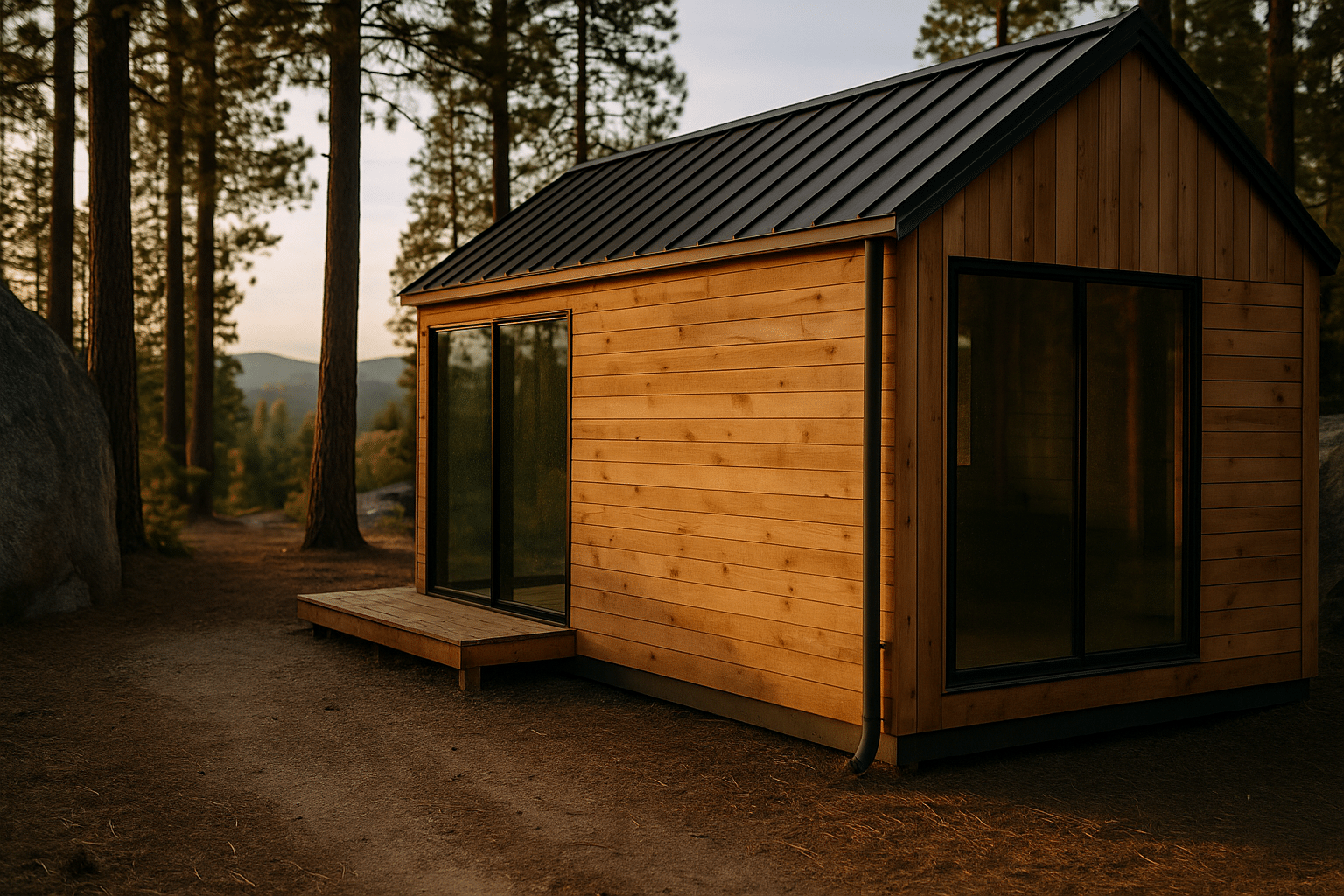

Modern prefab cabins are rewriting the rulebook for small-space living, remote getaways, and accessory housing. Factory-built precision, condensed timelines, and predictable costs have made offsite construction a practical path for many homeowners, land stewards, and hospitality hosts. Studies of industrialized building show time savings commonly between 20% and 50% compared with conventional site-built methods, alongside reduced waste and tighter quality control. That matters when schedules are tight, trades are scarce, or your site is hard to reach. Add contemporary design language—clean lines, generous glazing, and natural materials—and the appeal is clear: you can order a refined retreat without orchestrating a months-long ground-up build.

Outline of this guide:

– What to know before you buy: timelines, budgets, and how prefab differs from site-built.

– 13 cabin concepts you can order now: sizes, price ranges, and ideal use-cases.

– Materials and performance: structure choices, insulation, windows, and comfort systems.

– Delivery and approvals: transport limits, foundations, permits, and realistic logistics.

– Decision guide and conclusion: how to compare options and move forward with confidence.

Why this matters now: several trends converge in favor of prefabrication. Remote work enables longer stays in secondary locations. Communities increasingly allow accessory dwellings, expanding opportunities for backyard studios or rental units. Meanwhile, weather volatility pushes demand for higher-performing envelopes, wildfire-aware detailing, and resilient services that prefab builders routinely integrate. Cost-wise, finished cabins typically land in a broad range of about $150 to $400 per square foot depending on region, materials, and complexity, with small off-grid models sometimes below that range and high-spec glass pavilions above it. Lead times often run 6 to 12 weeks for production after approvals, then one to four weeks on-site for foundation, crane set, and hookups—sometimes faster for panelized kits assembled locally.

In the sections that follow, you’ll find a field guide to 13 cabin archetypes that are widely available to order right now. Rather than chasing flashy claims, we focus on practical specifications, credible price brackets, and the trade-offs that matter: assembly speed, transport constraints, climate suitability, and total ownership costs. Sprinkled in are small moments of imagination—because a cabin is more than a box; it’s the sound of rain on a metal roof, the cedar’s soft scent after a hot day, and the quiet that arrives when the door slides shut.

13 Modern Prefab Cabins You Can Order Now

Here are thirteen contemporary prefab cabin concepts commonly offered as modular, panelized, or turnkey units. Prices are indicative for the lower 48 U.S. states; remote sites, heavy snow or wind loads, premium finishes, and difficult access can add materially. Think of these as starting points to align scope, budget, and site conditions.

1) Micro A-Frame (120–200 sq ft)

– Base price: roughly $25k–$60k as a finished shell; add $10k–$25k for full interior build-out.

– Highlights: fast assembly, compact footprint, steep roof sheds snow; loft option for storage.

– Ideal for: weekend hideaway, backyard office, or sauna-adjacent changing room.

2) Rustic Studio Pod (160–280 sq ft)

– Base price: about $35k–$75k turnkey.

– Highlights: cedar or thermally modified cladding, simple rectangle plan, integrated deck.

– Ideal for: writing studio, guest sleepover, or short-stay rental.

3) Glass Pavilion Cabin (300–700 sq ft)

– Base price: approximately $140k–$280k depending on glazing package.

– Highlights: floor-to-ceiling windows, minimal structure, radiant floor or compact heat pump.

– Ideal for: scenic sites with privacy; star watching; shoulder-season stays.

4) Scandi Box Cabin (400–800 sq ft)

– Base price: roughly $110k–$240k turnkey.

– Highlights: clean lines, matte metal roof, flexible one-bedroom layouts, efficient kitchen and bath core.

– Ideal for: year-round living in temperate climates or as a tasteful guest house.

5) Lofted Tiny Cabin (250–450 sq ft)

– Base price: around $55k–$130k depending on cube height and stair type.

– Highlights: sleeping loft over kitchen/bath, big windows, clever storage under stairs.

– Ideal for: single occupant or couple; trailhead micro-lodge.

6) Two-Bed Family Cabin (600–900 sq ft)

– Base price: approximately $160k–$320k for two modules plus set and finish.

– Highlights: true bedrooms, full kitchen, stackable modules for future expansion.

– Ideal for: small families, long-term rentals, or a downsized primary home.

7) Off-Grid Adventure Cabin (200–500 sq ft)

– Base price: about $75k–$210k plus site systems.

– Highlights: prewired for solar, battery closet, high-R envelope, propane cooktop option, composting or incinerating toilet readiness.

– Ideal for: remote parcels, hunting/fishing basecamp, or wildfire-aware settings.

8) Coastal Stilt Cabin (400–900 sq ft)

– Base price: roughly $170k–$350k excluding specialized foundations.

– Highlights: elevated floor system, corrosion-resistant fasteners, impact-rated glazing where required.

– Ideal for: flood-prone areas, marsh edges, or lakefront with seasonal surges.

9) Mountain Chalet Module (600–1,200 sq ft)

– Base price: approximately $220k–$480k depending on snow load and spans.

– Highlights: vaulted living room, deep eaves, triple-pane windows, mudroom entry.

– Ideal for: alpine climates, heavy snow, winter sports hubs.

10) ADU Studio Cabin (250–400 sq ft)

– Base price: around $70k–$140k turnkey.

– Highlights: code-compliant ADU layouts, privacy glass along lot lines, compact mechanical closet.

– Ideal for: backyard residence, caregiver suite, or rental income.

11) Sauna + Plunge Cabin (80–160 sq ft sauna plus deck)

– Base price: about $18k–$48k for the heated volume; decking and plunge tub extra.

– Highlights: thermal-grade woods, insulated door, tempered window, roof venting.

– Ideal for: wellness routines, recovery zones, and cold-climate relaxation.

12) Work + Stay Flex Cabin (300–600 sq ft)

– Base price: roughly $95k–$210k depending on office built-ins and acoustic upgrades.

– Highlights: integrated desk wall, sound-dampened partition, convertible guest bed.

– Ideal for: hybrid workers, creators, and on-site managers.

13) Accessible One-Level Cabin (500–900 sq ft)

– Base price: approximately $150k–$310k depending on accessibility features.

– Highlights: single-floor plan, 36-inch clearances, roll-in shower, low thresholds, lever handles.

– Ideal for: aging in place, inclusive guest lodging, or mobility-friendly retreats.

Across these models you’ll see common structural approaches: panelized insulated walls assembled on-site for smaller units; full modules craned into place for mid-size layouts; and hybrid systems that blend floor cassettes with site-built roofs to ease transport height limits. Finish packages typically scale from durable, value-driven interiors to high-spec options like tongue-and-groove ceilings, engineered oak floors, and composite decking. The key is to map the model to your site and purpose, then fine-tune the envelope and mechanicals for your climate.

Materials, Structure, and Energy Performance

Prefab cabins earn their reputation for comfort and efficiency through disciplined assemblies and repeatable detailing. Most use one of three primary structures: conventional wood framing, structural insulated panels (SIPs), or engineered mass timber such as cross-laminated panels for select elements. Wood framing remains versatile and familiar to inspectors. SIPs combine insulation and sheathing in a single panel, improving airtightness and speeding installation. Engineered timber excels for longer spans and warm interior finishes, though it often carries a premium and added transport planning.

Insulation values vary by region and code, but a typical high-performance specification would target walls in the R-21 to R-35 range, roofs from R-38 to R-60, and floors around R-30 where crawlspaces are exposed. Airtightness—often overlooked—is a major comfort driver; factory-controlled sealing can reduce drafts and energy drift over time. For glazing, many cabins now offer double-pane low-e units with U-factors around 0.25–0.30 as standard, with triple-pane packages dropping U-factors toward 0.17–0.22 for cold or noisy sites. Window-to-wall ratio deserves thoughtful tuning: more glass equals more views and passive gain, but also higher heat loss without the right coatings and shades.

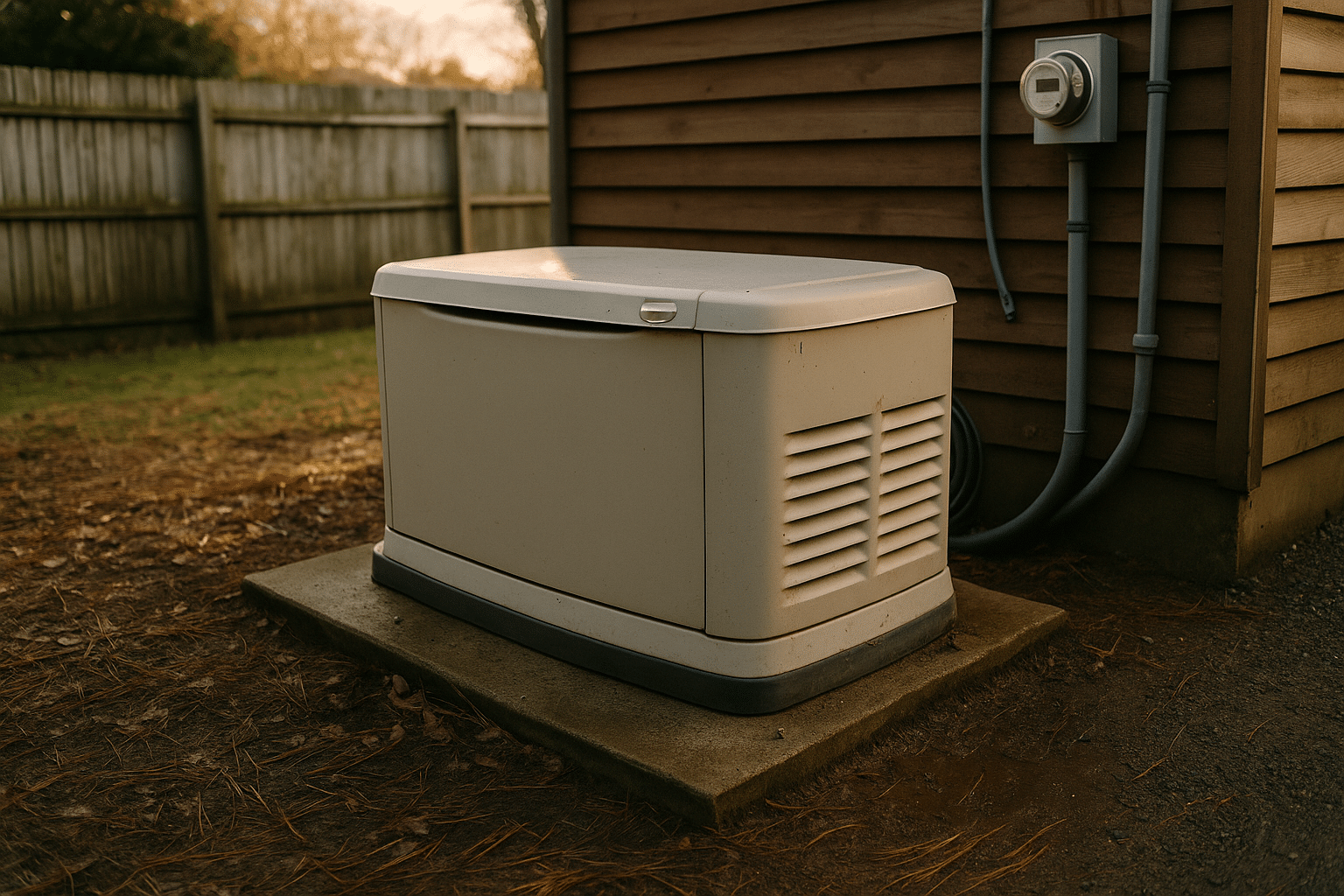

Mechanical systems tend to favor compact, efficient solutions: ductless heat pumps for heating and cooling, radiant electric in smaller footprints, and heat-pump water heaters where utility rates support them. Balanced ventilation via ERV or HRV preserves indoor air quality, especially in tight envelopes. In off-grid or resilience-focused scenarios, a 2–6 kW photovoltaic array, a 10–20 kWh battery, and propane or wood backup are common pairings. Material choices can widen the resilience envelope: metal roofing with Class A fire rating, fiber-cement or charred wood cladding for ember resistance, and mineral wool insulation for noncombustibility.

Durability also relates to moisture control. Best practice details include ventilated rainscreens behind siding, continuous flashing at penetrations, and generous roof overhangs. In snowy climates, added roof pitch and robust ice-dam protection reduce maintenance headaches. Factory production often cuts material waste by 15–30% versus conventional sites due to precise takeoffs and protected storage. That efficiency shows up not just in sustainability metrics but in the long-term look and feel of your cabin: straight drywall, square openings, quieter floors, and less seasonal movement.

Finally, the tactile elements matter as much as numbers. Natural wood interiors can be sealed with low-VOC finishes; composite decks resist splinters and stains; matte metals weather gracefully. When you run your hand along a slightly knotty cedar wall or hear rain tapping a corrugated roof, you’re reminded that performance is a stagehand supporting the show, not the star itself.

Delivery, Permits, Site Prep, and Total Cost of Ownership

Ordering a prefab cabin is straightforward; delivering and legalizing it is where most timelines are won or lost. Transport regulations typically allow modules up to about 14 feet wide on standard routes; widths beyond that usually require escorts, route surveys, and added fees. Heights above roughly 13 feet 6 inches trigger additional planning, which is why many builders ship low-profile modules and complete roof assemblies on-site. Rural or steep access may necessitate smaller modules or panelized packages carried in by shorter trucks.

Foundations depend on soil, frost depth, and loads:

– Helical piles: quick to install, minimal excavation, great for tree-sensitive sites.

– Concrete piers or stem walls: durable, familiar to inspectors, good for sloped lots.

– Slab-on-grade: efficient for mild climates; adds thermal mass and straightforward plumbing runs.

– Elevated frames for flood zones: engineered to local requirements, with breakaway elements where mandated.

Permitting varies by jurisdiction, but expect zoning checks (use type, setbacks, height), building permit for the structure, and separate reviews for septic, well, or utility connections. In many places, accessory dwellings are now prescriptively allowed, yet design standards and parking rules still apply. Timelines range from two weeks to several months; submitting a complete package—plan set, site plan, structural details, and energy documentation—speeds approvals. Realistic scheduling looks like this: design and approvals (2–8 weeks), factory production (6–12 weeks), site prep (1–3 weeks), set day with crane (1–2 days), and final connections and inspections (1–3 weeks).

Costs beyond the cabin itself can be significant. Typical ballpark adders include:

– Site surveys, geotechnical, and engineering: $2k–$10k depending on complexity.

– Foundation and utilities: $10k–$40k, more for long trenching or rocky sites.

– Delivery and crane: $3k–$15k depending on distance, module count, and lift radius.

– Permits and fees: $1k–$8k with local variation.

– Contingency: 10–15% of total project to handle surprises like soil issues or access work.

Operating costs hinge on envelope quality and energy rates. A well-insulated 400–600 sq ft cabin with a heat pump can see modest monthly energy use, often 250–500 kWh in shoulder seasons and higher during weather extremes. Maintenance remains manageable if you plan for it:

– Recoat exterior wood every 3–7 years depending on climate and exposure.

– Inspect roofs and flashings seasonally; clear gutters and snow loads as needed.

– Service mechanicals annually; replace filters for ERV/HRV and heat pumps on schedule.

– Check foundation anchors and tie-downs after major storms.

Financing options include construction-to-permanent loans for real-property installations, unsecured personal loans for smaller builds, and specialized products for accessory dwellings. Insurers will ask about foundation type, distance to hydrants, wildfire mitigation, and monitored alarms; providing those details up front yields cleaner quotes. Overall, a transparent, line-item budget and a preconstruction meeting with your builder, crane operator, and inspector are the quiet heroes of a smooth set day.

Conclusion: Choosing Your Cabin With Confidence

With 13 viable cabin archetypes on the table, the clearest path forward is methodical rather than hurried. Start with purpose: weekend retreat, full-time downsizing, workspace, or income unit. Purpose guides everything—size, envelope performance, mechanicals, and storage. Next, map your site: sun paths, wind exposure, snow drifting, trees worth keeping, arrival sequence, and utility routes. A simple bubble diagram of views, privacy, and outdoor spaces will often reveal the right plan before you commit to details.

Budget honestly by layering costs, not just the cabin sticker price. Include foundation, utilities, delivery, crane, permits, soft costs, and a contingency. Request itemized quotes that show what is included and what the site crew must handle. When comparing options, a simple scoring matrix helps: rate each candidate on envelope performance, layout fit, transport complexity, finish durability, schedule, and total cost. The high scorer may not be the least expensive; it will be the one that best serves your purpose and site.

Before ordering, verify code requirements with your local building department and confirm any homeowners’ association guidelines. Ask for stamped structural plans, energy compliance documentation, and an installation manual aligned to your foundation type. Request samples of key finishes you will touch daily—flooring, cabinet fronts, hardware—because tactile quality shapes long-term satisfaction more than catalog photos do. Finally, plan for the first year: snow shovels stored near the entry, exterior outlets for string lights, a hose bib where you actually need it.

Imagine your first evening in the cabin: windows glowing, kettle humming, a faint resin scent rising from warm timber. That moment arrives not by luck, but by steady decisions made in the right order. Choose a model that matches your climate and routine, invest in the envelope, and keep logistics realistic. Do that, and your prefab cabin becomes more than a purchase—it becomes a place that quietly works, season after season.