Whole-House Generator Installation Near You: A Homeowner’s Guide

Outline

– Why local context matters for whole-house generators and how “near me” choices improve safety and reliability

– Sizing methods, load priorities, and fuel options with practical examples

– Portable vs. standby vs. battery storage: performance, noise, and ownership costs

– Permits, codes, site prep, and utility coordination your installer will manage

– Installation day, realistic pricing, maintenance, and a checklist for hiring nearby pros

Why Whole-House Generators Matter in Your Area

Power outages are more than an inconvenience; they disrupt heating and cooling, refrigerators, medical devices, remote work, and security systems. A whole-house generator restores routine quickly by detecting an outage and transferring your home to a dedicated power source within seconds. Local knowledge is crucial. Weather patterns, lot sizes, fuel availability, and municipal codes vary widely, and those differences influence the right equipment, where it sits, how it vents, and which permits you need. A neighbor’s setup may look similar, but the details that make it safe and compliant are nearly always local.

Data underscores the value of preparedness. In recent years, U.S. customers experienced several hours of outage time on average, and storms remain a major driver of interruptions. Coastal communities face wind and salt-air exposure, plains regions contend with lightning and ice, and urban neighborhoods see tree-related and equipment failures. Your installer’s familiarity with regional outage causes helps tailor recommendations, from enclosure materials and pad design to surge protection and load management strategies. The result is a system that not only runs but endures, even as seasons and stress on the grid change.

Local context affects performance and peace of mind in practical ways:

– Fuel logistics: Natural gas pressure can sag during cold snaps; propane delivery routes may be delayed after storms; diesel storage needs careful conditioning.

– Noise ordinances: Many towns specify daytime exercise windows and maximum decibel levels at the lot line.

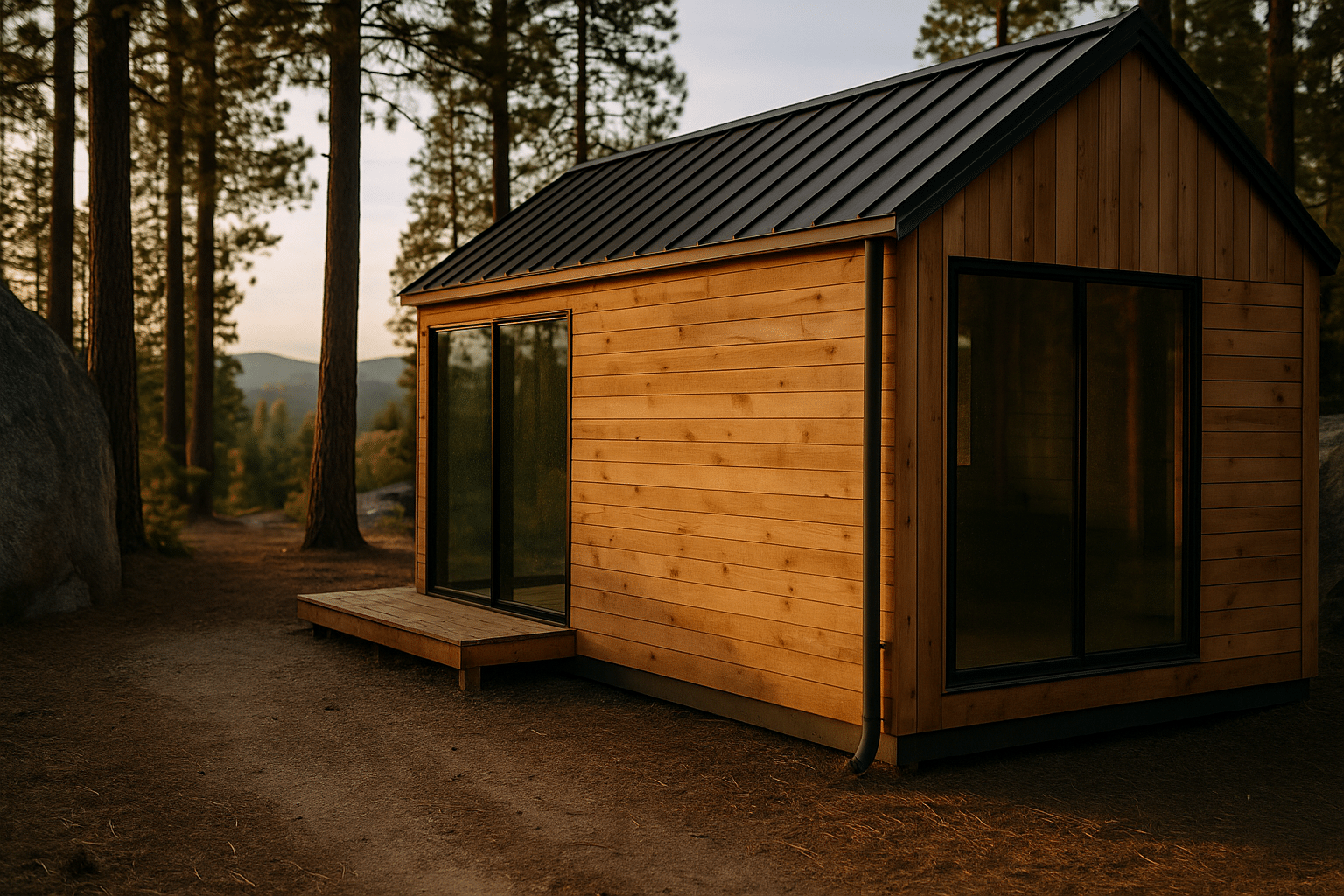

– Setbacks and clearance: Common rules require several feet from openings and property lines, and some areas add wildfire-defensible space or flood elevation requirements.

– Utility coordination: A nearby pro typically knows who to call and how to schedule meter pulls, inspections, and service-entrance work without lengthy delays.

Finally, the “near me” factor impacts support after installation. Routine maintenance, emergency service, and warranty claims move faster when the crew is minutes—not hours—away. In a storm, that difference can protect perishable food, maintain climate control, and keep sump pumps running. When you combine reliable power with local expertise, you turn a vulnerable moment into a manageable blip.

Sizing Your System and Choosing Fuel: Gas, Propane, or Diesel?

Right-sizing begins with a load calculation. Instead of guessing, a qualified installer will total the running wattage and the higher starting (surge) wattage of large appliances. Central air, well pumps, heat pumps, electric ranges, and dryers often drive capacity. A common approach is to select only “must-run” circuits—refrigeration, heating or cooling, lighting, internet, medical devices—and manage others with smart load-shedding modules so the generator stays within its rating. For many homes, that yields 12–18 kW. If you want most circuits active, a range of 18–26 kW is typical for mid-sized houses, and larger homes with multiple HVAC systems may use 30–48 kW.

Fuel choice is the next pivotal decision:

– Natural gas: Convenient and continuous supply, no on-site tank, cleaner combustion. Consider supply pressure during peak demand; your installer will verify available BTU capacity from the meter to ensure adequate flow at full load.

– Propane: Stored on-site in aboveground or buried tanks, widely available in rural settings, stable over time. Plan for delivery timing after storms and size the tank (commonly 250–500 gallons) to cover several days of operation.

– Diesel: Strong torque for heavy loads and commercial-grade reliability. Requires on-site storage with periodic fuel conditioning; more frequent maintenance may apply compared with gaseous fuels.

Fuel consumption varies by size and load. As a rough guide, a 20 kW unit at half load may use about 2–3 therms of natural gas per hour (or 1.6–2.0 gallons of propane). At full load, that can roughly double. Diesel consumption depends on engine displacement and load factor; plan for several gallons per hour at higher outputs. The goal is not to oversize and waste fuel, nor to undersize and risk nuisance trips. Smart load management lets a moderately sized unit power big loads sequentially, trimming cost while preserving comfort.

Other practical criteria inform the decision:

– Climate: Colder regions favor fuel heaters and cold-weather kits for gaseous engines; diesel performs well in cold with winter blends and block heaters.

– Noise: Larger engines can be louder; acoustically insulated enclosures reduce impact, and placement matters.

– Maintenance: Gaseous-fueled units typically require oil and filter changes every 100–200 hours; diesel schedules can be similar but demand closer fuel-care attention.

– Total cost of ownership: Account for equipment price, pad, gas plumbing or tank, electrical work, permits, and annual service. Many households see totals in the general range of several thousand to multiple tens of thousands depending on scope and size.

By marrying accurate load data with fuel realities and local supply conditions, you arrive at a balanced system: sufficient capacity, efficient operation, and accessibility to fuel when you need it most.

Portable, Standby, and Home Battery: How They Compare When the Grid Fails

Before committing to a whole-house generator, it helps to place it alongside alternatives. Portable generators are affordable and flexible, but they require manual setup, extension cords or a transfer device, frequent refueling, and strict safety practices. They are suited for short outages and a handful of circuits. Whole-house standby systems, by contrast, are permanently installed, start automatically, and integrate with your electrical panel through an automatic transfer switch (ATS). They handle high-surge loads like air conditioners without juggling cords, and they exercise themselves weekly to stay ready. Battery-based backup, often integrated with solar, delivers silent operation and instant transfer, but storage capacity can be limited for long, cloudy outages unless expanded at notable cost.

Key differences emerge in real-life use:

– Runtime: Standby units can run for days with natural gas or a large propane tank; portable models are constrained by fuel cans; batteries offer finite kWh until recharged.

– Load capability: Standby systems comfortably manage multiple large appliances with load-shedding intelligence; portables struggle with central HVAC; batteries excel at electronics and lighting but may not sustain heavy loads without large, modular packs.

– Safety and emissions: Properly installed standby units vent outdoors with clearances; portables must never operate in garages or near openings; batteries have no on-site combustion.

– Noise and placement: Portables tend to be louder and are used in temporary positions; standby enclosures attenuate sound; batteries are nearly silent and wall-mounted indoors or in garages.

Total cost of ownership also clarifies the picture. Portables can be obtained for a modest sum but add accessories, fuel cans, transfer devices, and time spent managing them. Standby systems require an upfront investment but deliver automatic operation, higher capacity, and fewer lifestyle disruptions. Batteries reduce maintenance and emissions but may require careful energy budgeting during extended storms. For many households where heating, cooling, medical equipment, or well pumps are critical, a standby generator offers a strong balance of resilience and convenience. In regions with reliable gas supply and frequent multi-hour outages, that balance becomes even more compelling. If your outages are brief and infrequent, or you already have solar, a battery or hybrid approach can be practical—your local installer can model scenarios so you understand trade-offs before you commit.

Permits, Codes, and Site Preparation: What Local Installers Handle

Professional installers do far more than place a unit and connect wires. They navigate permits, codes, inspections, utility coordination, and site conditions that determine how your system performs for years. Expect at least two permits in many jurisdictions: electrical and gas/mechanical. Zoning checks confirm setbacks from property lines and clearance from doors, windows, and vents—often several feet per published standards. In wildfire-prone or floodplain areas, additional rules govern defensible space and elevation above grade. Your contractor will typically submit drawings showing the pad location, conduit runs, gas piping, and the automatic transfer switch (ATS) relative to the main service equipment.

Codes exist to keep you safe:

– Electrical: Service-entrance rated ATS units, conductor sizing, proper grounding and bonding, and surge protection are common requirements.

– Fuel: Gas piping sized for BTU demand, pressure testing, drip legs where required, and approved materials and fittings.

– Venting and clearance: Minimum distances to avoid exhaust intrusion, combustible materials, and ignition sources.

– Noise: Municipal ordinances can limit decibels at property lines; placement and acoustic fencing can help.

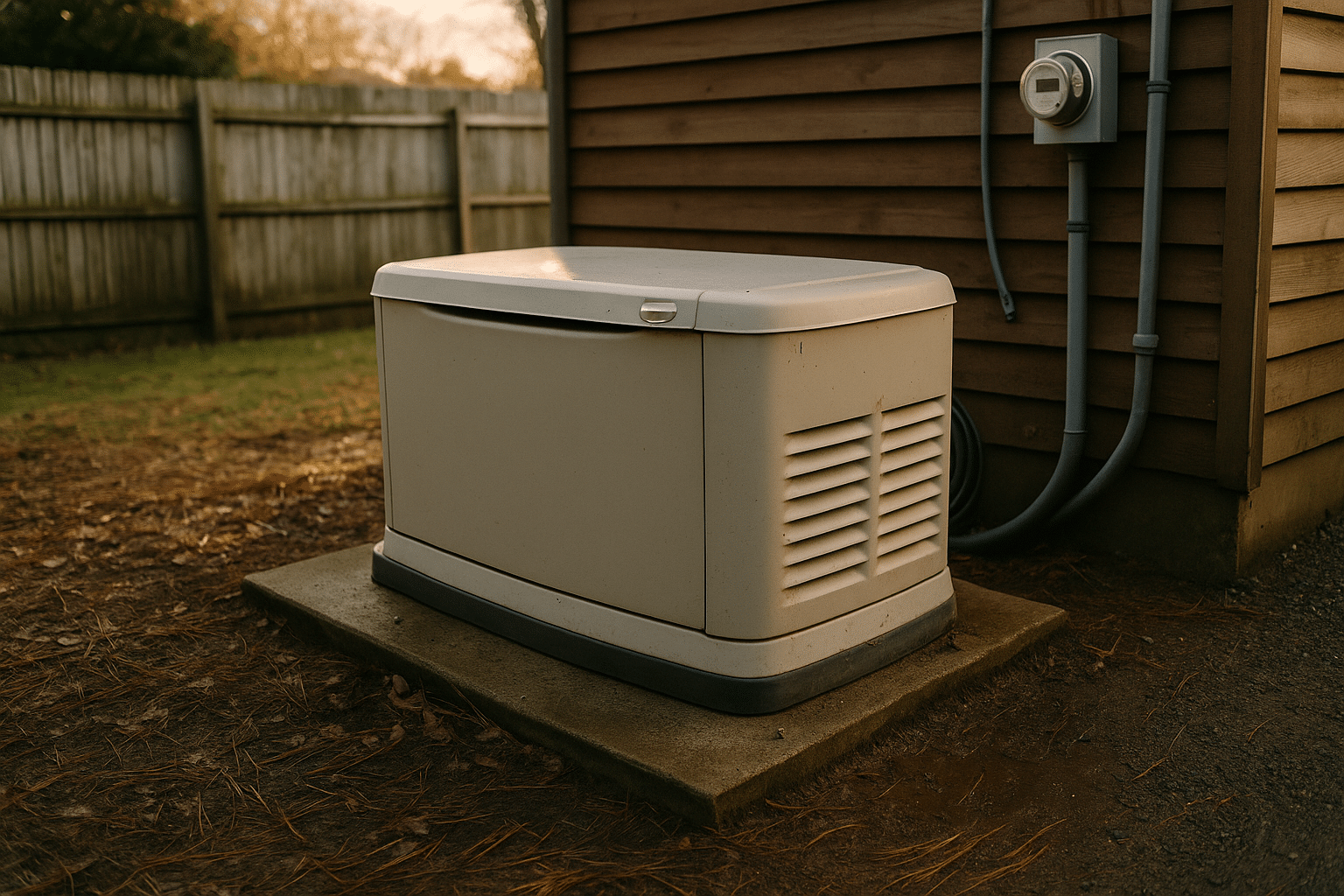

Site preparation balances durability with drainage and maintenance access. A composite or concrete pad provides a stable, level base, with crushed stone for drainage. Installers plan for service clearances so panels and filters are easy to reach. Conduit runs are laid out to minimize bends, protect conductors, and keep the installation tidy. Gas lines are routed with protection from impact, and trenches are backfilled to required depth and compaction. If you rely on propane, the tank location and size are coordinated with your supplier, and cathodic protection may be specified for buried tanks.

Utility coordination can be the trickiest calendar item. For service-entrance ATS installations, the power company may need to de-energize the meter and later return for inspection sign-off. Experienced local firms know scheduling patterns and plan work to avoid leaving you without power overnight. They also perform a start-up checklist: checking gas pressure and leak integrity, verifying voltage and frequency under load, exercising load-shedding modules, and training you on weekly exercise settings. When that first storm rolls through, you want a system that simply works; the path to that outcome is paved with well-managed permits, careful site prep, and thorough commissioning.

Installation Day, Costs, Maintenance, and How to Vet a Local Pro

Once permits clear and materials arrive, installation day follows a sequence designed to minimize downtime. Crews set and level the pad, craning or rolling the generator into place. Electrical teams install the ATS—either adjacent to or integrated with your main service—and reroute feeders and selected branch circuits. Gas technicians pull and pressure-test piping, add sediment traps if required, and verify regulator sizing. After conductors and piping pass inspection, the system is commissioned: oil and coolant checks (if liquid-cooled), battery connections, control programming, and a live transfer test under load. Many projects finish in one to two days; larger service upgrades or trenching can extend the timeline.

Budget realistically by separating line items:

– Equipment: Generator and ATS represent a major share; capacity and enclosure type affect price.

– Site work: Pad, trenching, gas piping or propane tank work, and panel modifications.

– Permits and inspections: Municipal fees vary by region.

– Add-ons: Surge protection, cold-weather kits, sound attenuation measures, and remote monitoring.

– Labor: Electrical, gas/mechanical, and coordination time.

Totals often start in the mid four figures for smaller, essential-load systems and can rise into the tens of thousands for larger whole-home installations with service upgrades, long gas runs, or complex trenching. Ownership costs include annual maintenance—oil and filter changes, spark plugs as needed, valve adjustments on some engines, battery testing, and software updates. A reasonable plan is one professional service visit per year plus visual checks after major weather. Fuel budgeting matters too: schedule propane deliveries proactively and consider natural gas meter upsizing if your load is high.

Choosing a nearby installer is as important as the equipment itself. Look for:

– Licensing and insurance appropriate to electrical and gas work in your state or province.

– Documented load calculations and a written scope that lists circuits, fuel line sizes, pad type, and clearances.

– Clear warranty terms covering parts, labor, and response times.

– References from recent local projects and photos that show workmanship details.

– A maintenance program with defined costs and response procedures during storms.

Ask pointed questions: How will you verify gas capacity under peak heating load? What decibel level should I expect at the lot line? If the ATS is service-entrance rated, will you coordinate the utility disconnect and inspection? How will you configure load shedding for HVAC and well pumps? The answers reveal process maturity. In short, hire for proximity, clarity, and craft. A well-qualified local team turns a complex project into a smooth upgrade for your home’s resilience.

Conclusion: Local Expertise Turns Backup Power into Everyday Confidence

A whole-house generator is more than a machine; it is a plan for ordinary life to continue when the grid blinks. By choosing a nearby, well-regarded installer, you align your system with local codes, fuel realities, and neighborhood constraints, cutting through delays and uncertainty. Size it with intention, prepare the site carefully, and commit to regular maintenance. Do that, and outages become brief pauses rather than stressful events—power that feels almost routine, even when the weather is anything but.